Back to overview

Scroll

down

Clean water is critically important for a healthy environment. As a key resource for manufacturing our products, Stahl uses water in several ways. We dedicate significant resources to researching how we can reduce our water use, introduce water-based products, improve the quality of our water effluents and reduce water pollution in the value chain.

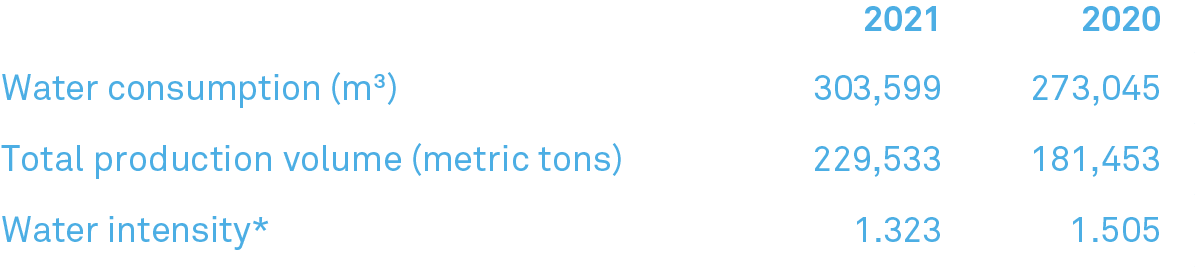

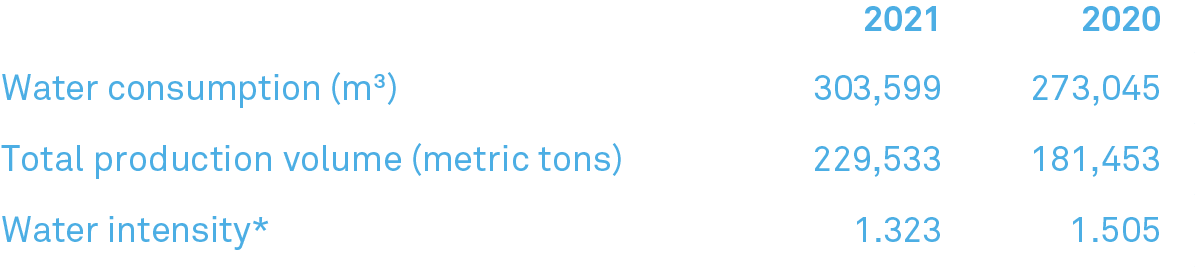

We use water from municipalities (public water) and ground water in our operations. Our manufacturing sites use water for cleaning tanks and pipes and for processing, heating and cooling. And we use water at our office and laboratory locations too. Our water usage increased in 2021 because of higher production volumes, but water consumed per metric ton produced (intensity) was lower in 2021 vs. 2020.

Total water consumption

Data verified and validated by Deloitte

*Intensity is related to production volumes (water consumption/production volume).

Water use at the Palazzolo site (Italy)

To help the community maintain a low level of groundwater, the (cooling) water at the Palazzolo manufacturing site in Italy is temporarily taken (i.e. not consumed) from a ground well, completely separated from production and is discharged into the adjacent river (Seveso). This specific use of water is approved by and follows the strict guidelines set by local authorities.

Data verified and validated by Deloitte

Water-based technology reduces the carbon footprint

Water-based technology has replaced petrochemical-based vehicles as a solvent in many commercial products. 56% of our turnover in 2021 is from water-based products (defined as containing >50% water and <15% co-solvent). LCA studies in 2021 reported a 30-50% reduction in carbon footprint for water-based products vs solvent-based equivalents.

Back

to top

Back to overview

Back

to top

Water-based technology reduces the carbon footprint

Water-based technology has replaced petrochemical-based vehicles as a solvent in many commercial products. 56% of our turnover in 2021 is from water-based products (defined as containing >50% water and <15% co-solvent). LCA studies in 2021 reported a 30-50% reduction in carbon footprint for water-based products vs solvent-based equivalents.

Please swipe for full visual

Data verified and validated by Deloitte

Water use at the Palazzolo site (Italy)

To help the community maintain a low level of groundwater, the (cooling) water at the Palazzolo manufacturing site in Italy is temporarily taken (i.e. not consumed) from a ground well, completely separated from production and is discharged into the adjacent river (Seveso). This specific use of water is approved by and follows the strict guidelines set by local authorities.

Please swipe for full visual

Total water consumption

Data verified and validated by Deloitte

*Intensity is related to production volumes (water consumption/production volume).

We use water from municipalities (public water) and ground water in our operations. Our manufacturing sites use water for cleaning tanks and pipes and for processing, heating and cooling. And we use water at our office and laboratory locations too. Our water usage increased in 2021 because of higher production volumes, but water consumed per metric ton produced (intensity) was lower in 2021 vs. 2020.

Clean water is critically important for a healthy environment. As a key resource for manufacturing our products, Stahl uses water in several ways. We dedicate significant resources to researching how we can reduce our water use, introduce water-based products, improve the quality of our water effluents and reduce water pollution in the value chain.