Back to overview

Scroll

down

We aim to reduce Stahl’s impact on the environment by preventing pollution through waste minimization, re-use, recovery and recycling. We avoid generating waste in the first place, and when there is waste, we aim to find useful outlets for it whenever possible.

Separating waste streams

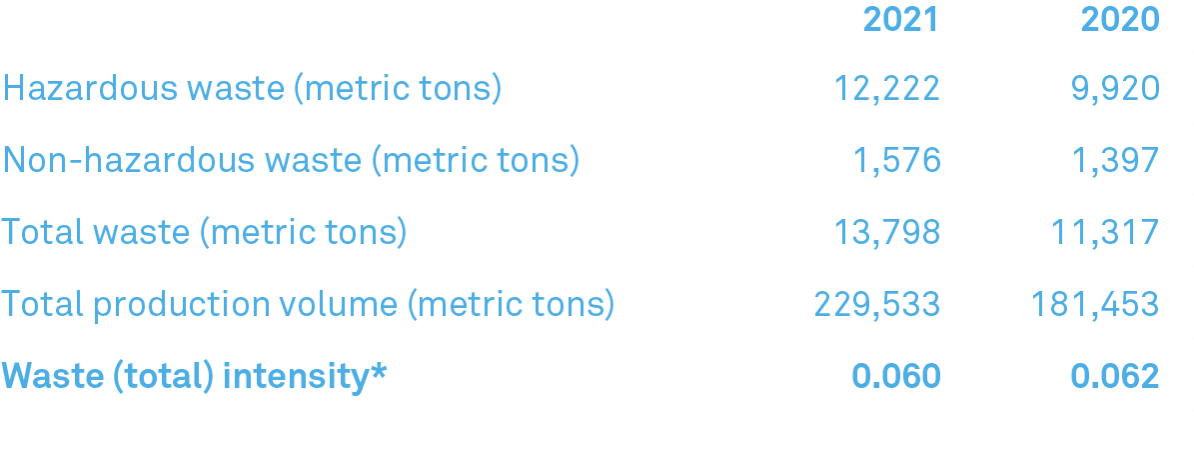

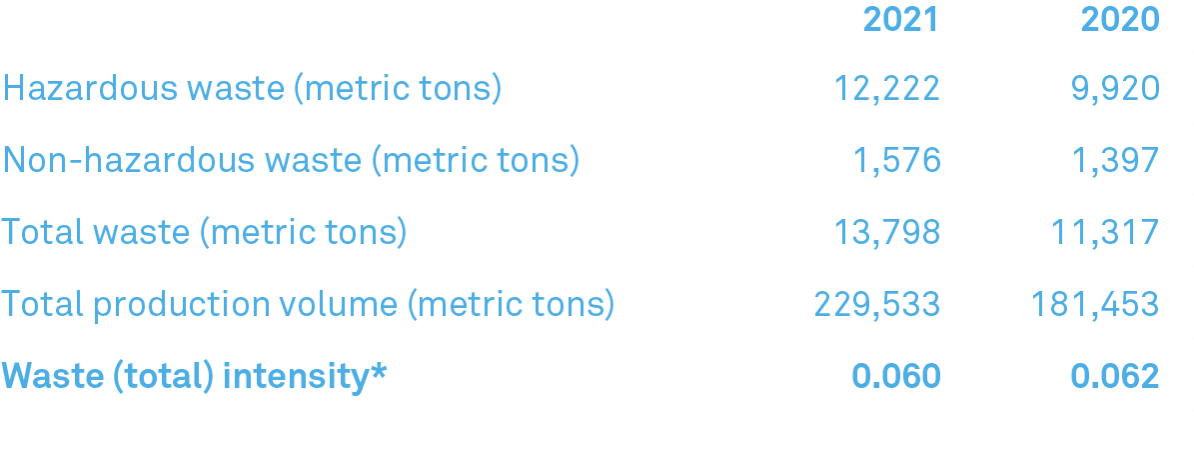

Stahl generates hazardous and non-hazardous waste, which we separate as waste streams for disposal. Hazardous waste comes from chemical-related sources: from our products, raw materials, process installations (such as sludge from wastewater treatment), laboratories and used packaging. Non-hazardous (non-chemical) waste includes glass, paper, wood, plastic, domestic and demolition waste. The quantity of waste increased in 2021 by 22% (vs. 2020) due to higher production volumes (+26% vs. 2020). Waste intensity dropped by 3%.

Data verified and validated by Deloitte

*Intensity is related to production volumes (water consumption/production volume).

Wastewater treatment

Most Stahl sites have on-site wastewater treatment installation, and where this is not the case, wastewater is collected by a third party and reported and processed as hazardous waste. In 2021, total wastewater sent to external treatment increased compared to 2020. A water treatment facility at the Waalwijk plant was commissioned in 2021 and will be built in 2022.

Data verified and validated by Deloitte

*Waalwijk (Netherlands), Calhoun (USA) and Toluca (Mexico).

Back

to top

Back to overview

Back

to top

Please swipe for full visual

Data verified and validated by Deloitte

*Waalwijk (Netherlands), Calhoun (USA) and Toluca (Mexico).

Wastewater treatment

Most Stahl sites have on-site wastewater treatment installation, and where this is not the case, wastewater is collected by a third party and reported and processed as hazardous waste. In 2021, total wastewater sent to external treatment increased compared to 2020. A water treatment facility at the Waalwijk plant was commissioned in 2021 and will be built in 2022.

Please swipe for full visual

Data verified and validated by Deloitte

*Intensity is related to production volumes (water consumption/production volume).

Separating waste streams

Stahl generates hazardous and non-hazardous waste, which we separate as waste streams for disposal. Hazardous waste comes from chemical-related sources: from our products, raw materials, process installations (such as sludge from wastewater treatment), laboratories and used packaging. Non-hazardous (non-chemical) waste includes glass, paper, wood, plastic, domestic and demolition waste. The quantity of waste increased in 2021 by 22% (vs. 2020) due to higher production volumes (+26% vs. 2020). Waste intensity dropped by 3%.

We aim to reduce Stahl’s impact on the environment by preventing pollution through waste minimization, re-use, recovery and recycling. We avoid generating waste in the first place, and when there is waste, we aim to find useful outlets for it whenever possible.